Vorto's CPO, Sam McLaughlin, details the increased demands supply chains are facing and the need for solutions which go beyond visibility to solve complexity.

Today's Supply Chains are Complex, Interconnected and Dynamic

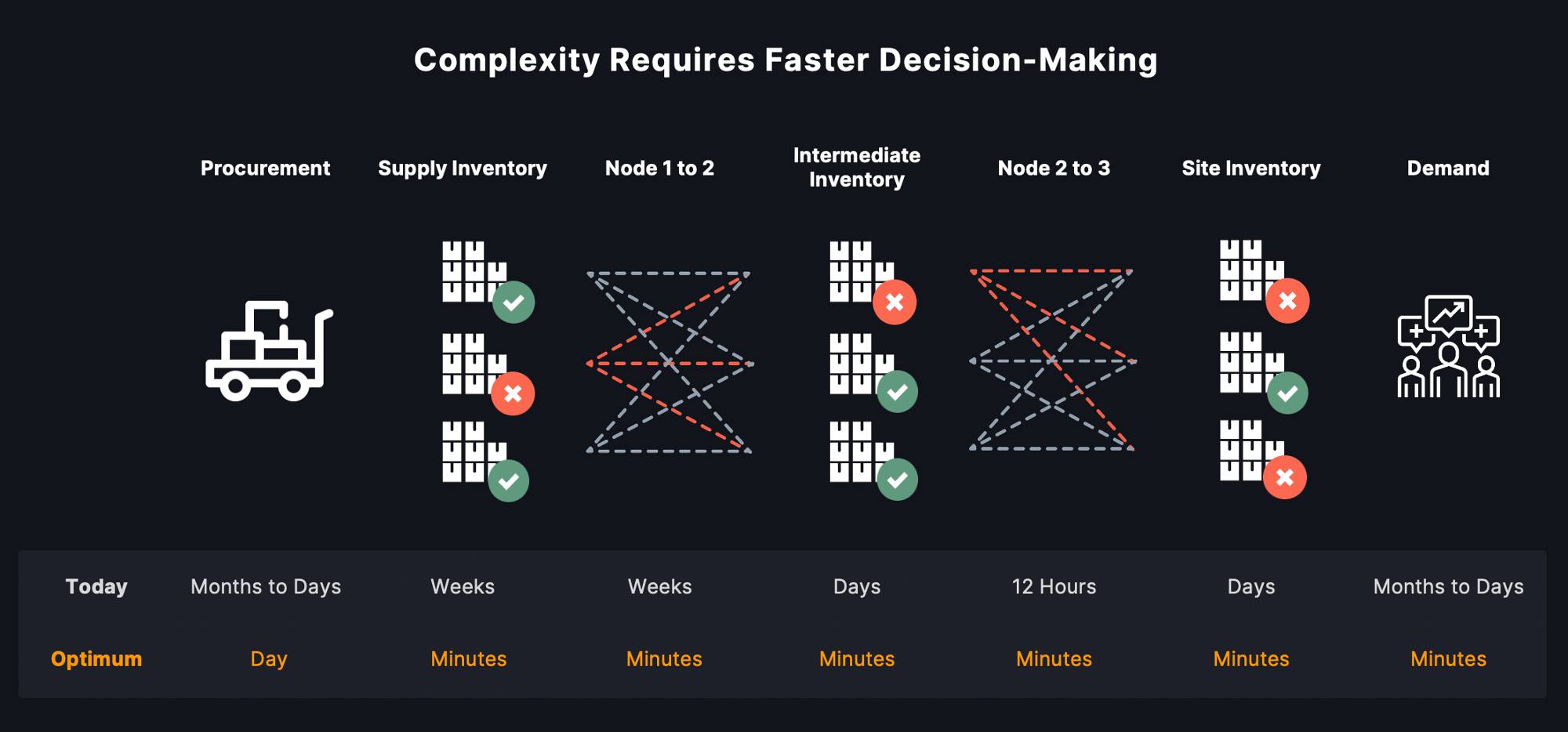

Today's Supply Chains are intertwined networks of numerous nodes between raw material provider and end customers. This complex network of suppliers, consumers, and carriers is further complicated by multiple siloed organizations spanning across procurement, logistics, and operations.

This interconnected network, like the image above, is so dynamic that when supply chain organizations analyze and develop a solution to a specific change in real time, that dynamic ends up again changing even before the implementation of the solution to the previous change.

A failure to optimally act in response to these challenges in real time results in depressed margins due to an increased Total Landed Cost (TLC – Cost of material + logistics), Non-Productive Time (NPT), and reduction in carrier asset utilization rates.

Digitization & Visibility Systems Fail to Solve this Supply Chain Complexity

Supply Chains need to make real time decisions to hundreds of questions like the following:

Answers to many more questions like the above must be found in real time under extreme time pressure.

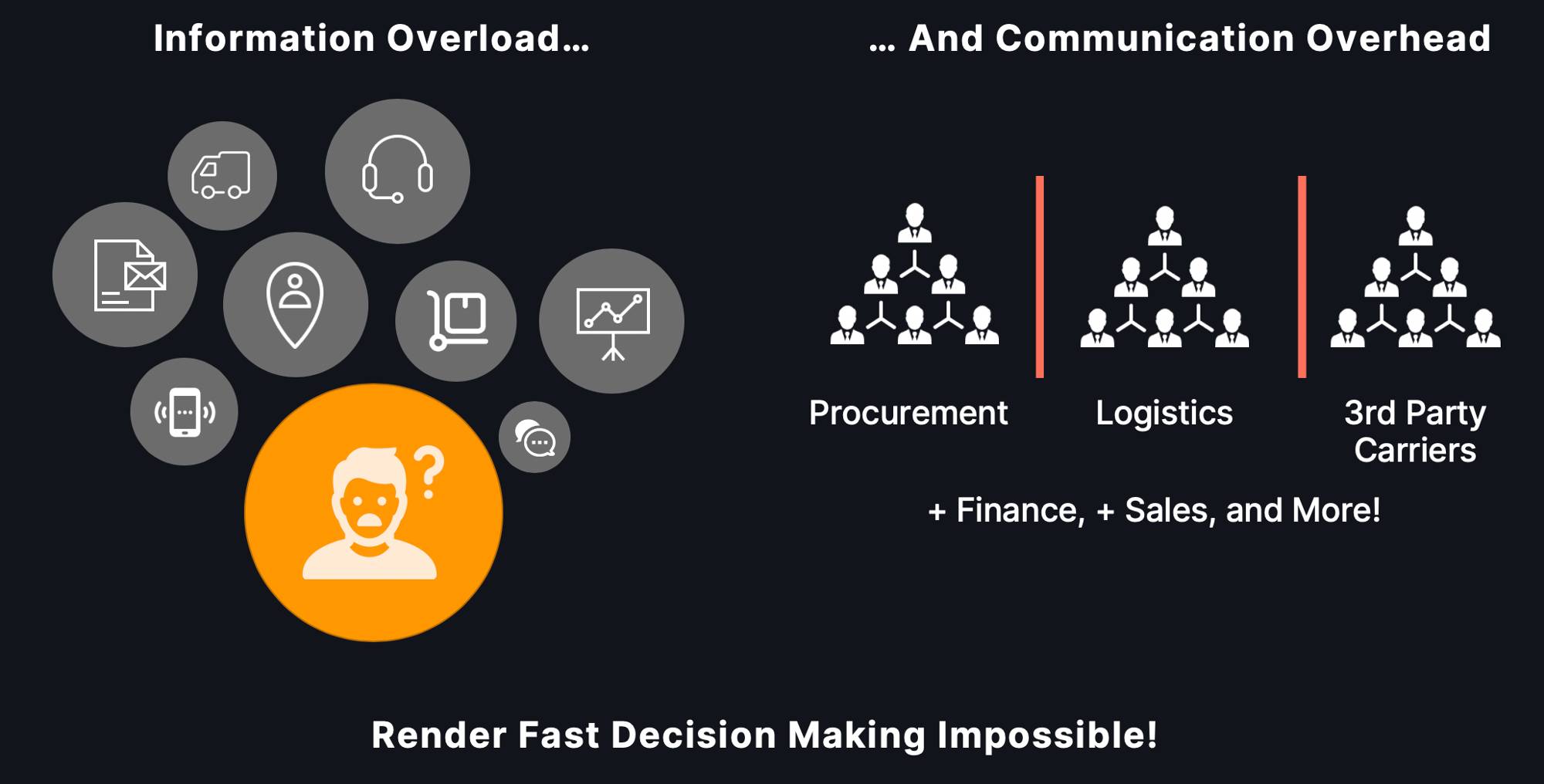

Current visualization and digitization tools collect a lot of data, convert inefficient manual workflows to digital workflows, and require large control rooms with lots of resources to spend a lot of time preparing, analyzing and communicating the data resulting in cognitive overload.

This leads to poor and slow decision making, and ends up costing organizations more than 30x the expense of the professionals making the decision! Businesses that rely on visualization tools to solve this supply chain complexity are unnecessarily sacrificing their margins.

VORTO's Digital Transformation Platform Saved Customers over $480 million in 2019

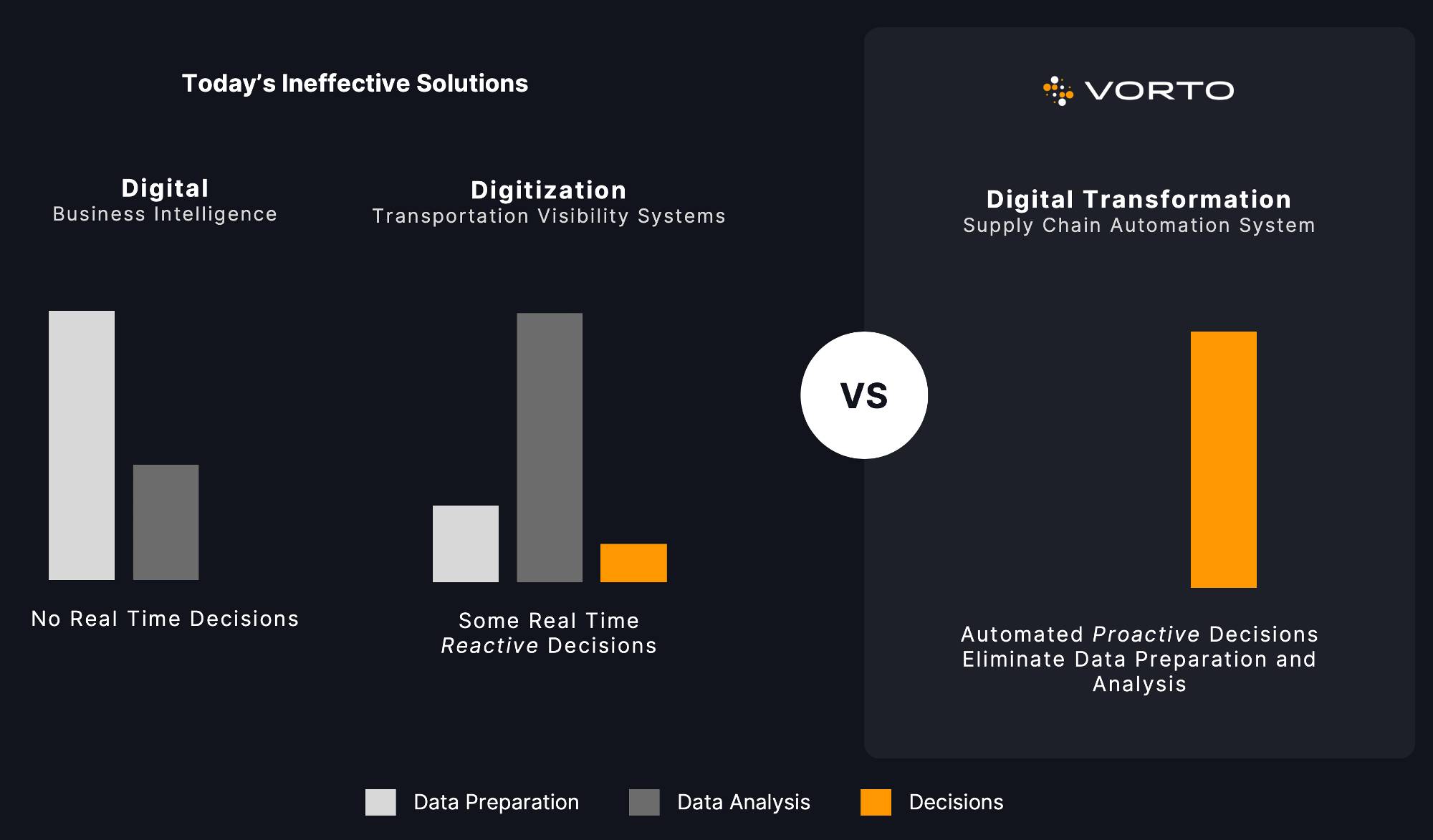

VORTO uses AI to eliminate cognitive overload by automating data preparation, analysis and decision making. Using VORTO's automated across demand planning, procurement, and logistics transforms supply chain from Digitization to Digital Transformation.

We recognized this significant opportunity for supply chain automation after first hand experiencing the level of complexity and inefficient solutions that create phenomenal stress and burnout among logistics and procurement professionals across industries.

That is why we built the VORTO platform to integrate and automate procurement, logistics, and 1st and 3rd party carrier management from purchase order to dispatch. Our platform has saved customers over $480 million in 2019 alone – not to mention the significant savings and efficiency gains seen by their suppliers and carriers as well.